Factory

Since its creation, Super Mousse has worked tirelessly to acquire and develop machinery, production equipment and mastery of advanced digital technologies used in design, molding and cutting techniques.

Super Mousse is proud of its technical team whose workforce has continued to grow: it has grown from 20 employees when the project was launched in 1994, to 200 employees including 40 managers in 2021.

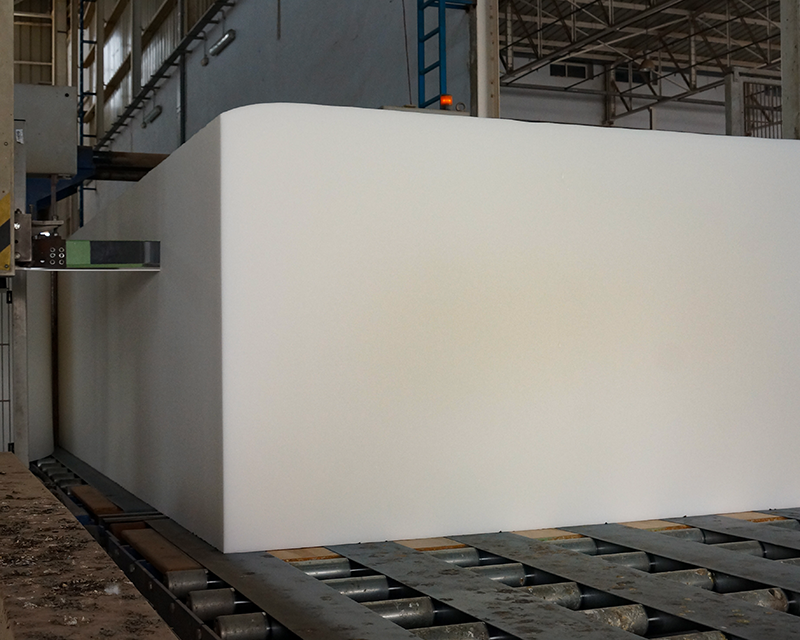

Foam production unit

The machine is intended for the continuous production of soft foam in different densities and sizes.

It is a mixture of several products which enter into an exothermic reaction after being mixed at a given pressure and temperature. This mixture is poured onto a conveyor rotating at a determined speed (depending on the density to be produced), the foam forms along the conveyor at the end of which the block passes through a hot drying chamber to finally arrive at a determined cutting-to-length machine.

Foam cutting unit

The production of the spring mattress

- Manufacture and assembly of springs

- Preparing the tapes using a machine called an automatic multi-pattern tape stitcher.

- Mounting handles and aerators: which consists of cutting the strips according to well-determined dimensions and the installation of the handle and aerator

- Enclose both ends of the strip and place the corresponding label.

- Preparing tablecloths using a quilting machine

- Overcasting of the tablecloth on the four sides to the desired dimensions, which facilitates the edging operation.

- Foam framing.

- Padding

- Laying tablecloth and band

- Border

- Finishing, checking and packaging